GREEN NDT SERVICES

INSPECTION

TAKEN TO NEW HEIGHTS

PROVIDING PHASED ARRAY ULTRASONIC TESTING AND TIME OF FLIGHT DIFFRACTION TO ENABLE UNINTERRUPTED PRODUCTION AND REAL-TIME RESULTS.

A HIGHER

LEVEL OF RELIABILITY

PROVIDING FULL SPECTRUM OF NDT METHODS FROM THE TRADITIONAL TO THE MOST ADVANCED.

WELCOME!

AS A SERVICE ORIENTED COMPANY WE UNDERSTAND THE IMPORTANCE OF QUALITY ASSURANCE

Green NDT has ingrained Quality and HSE to be an integral part of all management and execution functions. This culture designed with the characteristics of self-sustainability and continuous improvement commensurate with the company's Quality and HSE policies. Our inspection criterion is to carry out inspection of items as per the norms specified by the international codes & standards, client's specifications & drawings, and quality assurance plans provided by the client.

With the aim of minimizing non-conformity risks our teams of experienced and qualified engineers have developed credibility among manufacturers. We are committed to delivering high quality services to our customers that meet or exceed their expectations. Our customers are the most vital part of our company and we strive to give them a piece of mind. With Green NDT Services you can rest assured that every time you will get confident results.

PREVENTION OF DISASTERS IS A MAJOR CONCERN IN ANY INDUSTRY. NON DESTRUCTIVE TESTING AS A RELIABLE TOOL HAS PLAYED AN EFFECTIVE AND IMPORTANT ROLE IN THIS REGARD. DUE TO THE INCREASING DEMAND FOR MORE THOROUGH AND SAFE INSPECTION METHOD, WE OFFER A MORE INNOVATIVE MEANS OF DEFECT MEASUREMENT.

PHASED ARRAY ULTRASONIC TESTING (PAUT) & TIME-OF-FLIGHT DIFFRACTION (TOFD) FLAW DETECTION PROCEDURE HAS BEEN IMPLEMENTED TO ACHIEVE GOOD RESULTS AND SHOWN TO BE AN EFFECTIVE PROCEDURE FOR SIZE AND LOCATION DETERMINATION OF DISCONTINUITIES.

MODERN FIELD TECHNOLOGY FOR INSPECTION.

PERSONNEL QUALIFIED TO ASNT TC-1A.

REDUCED REPORTING TIME.

LEVEL III AUDIT TO ENSURE HIGH QUALITY, CODE COMPLIANT WORKMANSHIP.

NOT ONLY IS THE INTEGRITY OF THE CLIENT'S ASSETS OF PRIME IMPORTANCE, BUT INTEGRITY IN OUR RELATIONSHIP WITH THE CLIENT AND OUR INSPECTORS IS ALSO IMPERATIVE. IT IS THE RESULTING CLIENT AND EMPLOYEE TRUST AND LOYALTY THAT FUELS OUR GROWTH AND IS THE RECIPE OF OUR SUCCESS.

OUR GOAL IS TO PROVIDE YOU FULLY EQUIPPED, HIGHLY TRAINED, COMPETENT, AND EXPERIENCED INSPECTORS THAT YOU TRUST AND THAT TAKE CARE OF YOUR ASSET GIVING SUPERIOR RESULTS YOU CAN RELY ON WITH CONFIDENCE.

MODERN TECHNOLOGY

QUALIFIED INSPECTORS

REDUCED REPORTING TIME

ABOUT US

Green NDT Services was established in the year 2011 as a Non-Destructive Testing, Inspection and Consultancy Company to serve the needs of Industries ranging from Engineering Fabrication and Construction, to Marine Oil & Gas. Using our comprehensive range of in house and on site Non Destructive Testing facilities, we offer a degree of expertise and product knowledge to all industry sectors. We also offer a rapid response for advice by qualified and professional personnel.

Our work is critical to the integrity and safety of our clients' operations. We provide non-destructive testing and inspection services in Pakistan, Iraq and Afghanistan.

Our dedicated professionals, support the mechanical integrity and inspection programs for petroleum refineries, pipelines, power generation, pulp & paper, pharmaceutical and automotive.

With certified and well-equipped personnel supported by trained, experienced supervisors. We continue to build on our strong heritage of safety, quality and professionalism. We strive to maintain incident free work environments, to pursue advanced technical developments, and to support reliability programs that are expected and valued by our employees and clients.

OUR PHILOSOPHY

At Green NDT Services we are committed to continuous technological improvement, innovation and excellence. We strive to exceed our clients' expectations while providing safe working environments, maintaining the highest industry standards, and respecting the dignity of every employee. Our mission is to provide reliable, repeatable service. Our commitment is to employ the best resources, technology and methods available today. Our investment in quality, service and efficiency comes from our focus on discipline, exceeding client expectations, and continuous improvement that drives productivity.

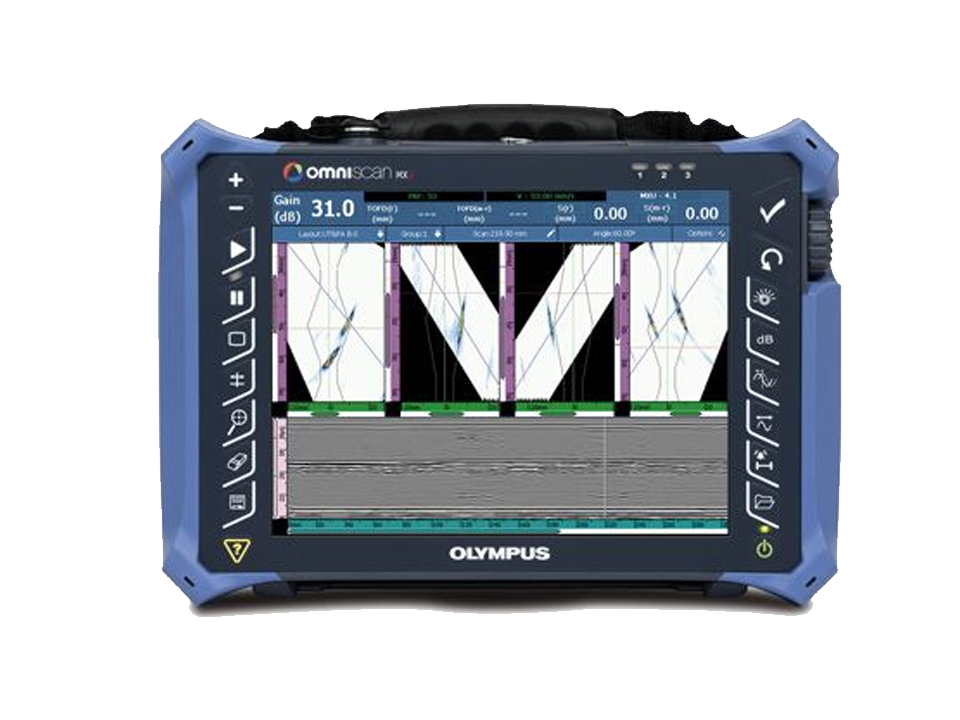

Phased Array Ultrasonic Testing

Utilizing multi-element probes, which are individually excited under computer control, a focused beam of ultrasound is generated. Software enables the beam to be steered. Two and three dimensional views can be generated showing the sizes and locations of any flaws detected.

Ultrasonic phased array systems can potentially be employed in almost any test where conventional ultrasonic flaw detectors have traditionally been used.

Weld inspection and crack detection are the most important applications, and these tests are done across a wide range of industries including aerospace, power generation, petrochemical, metal billet and tubular goods suppliers, pipeline construction and maintenance, structural metals, and general manufacturing. Phased arrays can also be effectively used to profile remaining wall thickness in corrosion survey applications.

Time of Flight Diffraction (TOFD)

Widely used in the oil and gas, petrochemical and power generation industries.

TOFD systems use a pair of ultrasonic probes sitting on opposite sides of a weld-joint or area of interest. The transmitter probe emits an ultrasonic pulse which is picked up by the receiver probe on the opposite side. In an undamaged part, the signals picked up by the receiver probe are from two waves – one that travels along the surface (lateral wave) and one that reflects off the far wall (back-wall reflection).

When a discontinuity such as a crack is present, there is a diffraction of the ultrasonic sound wave from the top and bottom tips of the crack. Using the measured time of flight of the pulse, the depth of the crack tips can be calculated automatically by trigonometry application.

Conventional Ultrasonic Testing

Ultrasonic Testing uses high frequency sound energy to conduct examinations and make measurements. This is a very useful and versatile non-destructive testing method. It is sensitive to both surface / subsurface discontinuities and the depth of penetration for flaw detection or measurement is superior to other NDT methods. Our typical UT inspection system consists of several functional units, which provide instantaneous results.

Thickness measurements are performed using a conventional flaw detector and a compression wave probe. The results are determined from the A-Scan. This A-Scan is also used for weld inspection. Our highly qualified and experienced technicians use the most advanced equipment and software for reporting and identification of defects and measurements of various applications for conformity.

Hardness Testing

Hardness Testing is carried out to determine the strength of various materials. Hardness is generally defined as a measure of the material’s resistance to scratching, deformation, or cutting.

A hardness test gauges this parameter by assessing the depth of an indent or incision made by a precisely shaped indenter applied to the material with an exact amount of force over a specified period of time. Appropriate candidates for hardness tests include structural steel, castings, forgings, welds, weld overlays, piping, machined parts and pressure vessels.

We use digital hardness testers which do not impair the future usefulness of the test piece and can be used when high degree of surface quality is important.

Magnetic Particle Testing

Magnetic Particle Testing is a Non-Destructive Testing method for detection of crack on or just below the surface of ferrous metals. It is a quick and reliable technique for detection and location of surface cracks. It can be applied to relatively rough and dirty surfaces. For maximum sensitivity fluorescent particles are used.

Green NDT Services utilizes Magnetic Particle Testing for all ferrous materials, such as carbon steel, low-alloy and cast iron. The main use of Magnetic Particle Testing is for welds and heat affected zones. We have well trained and experienced MPT technicians who will provide you with confident results.

Liquid Penetrant Testing

Liquid Penetrant Testing is used for crack detection to verify compliance and ensure safe operation. The examination involves applying a liquid to the surface of a material and leaving it to rest for a pre-determined period of time. The liquid, is easily visible under normal or special lighting conditions depending on the color.

The penetrant once applied penetrates the defects. When the penetrant fluid is washed off the surface and a developer applied, the defects where the fluid has penetrated are made visible. These spots are called indications. Acceptance criteria define whether or not the indication is non-acceptable (a defect) or not. Green NDT offers this service for both existing and new installation.

Coating Inspection

Our inspectors are equipped with all of the necessary field instrumentation to provide thorough surveillance. Comprehensive documentation is prepared detailing job quality and progress. This close oversight enables the inspectors to identify potential problems and recommend solutions before the work progresses to a point where costly rework is required.

Our painting inspectors monitor; pre-surface preparation, weather condition effects, surface preparation, confirmation of proper product applicability, product mixing, product application, wet/dry film thickness, recoat times, cure evaluations, product adhesion and coating discontinuities.

Visual Inspection

Visual Inspection (VI) is the most widely used non-destructive testing technique. Visual inspection is normally the first step in the examination process. Generally, almost any specimen can be visually examined to determine the accuracy of its fabrication, welding, surface defects, corrosion pits, general condition, degradation, blockages and foreign materials.

Visual Inspection means the inspection of equipment and structures using a combination of human senses such as vision, hearing, touch and smell. Green NDT has the necessary experience, expertise and knowledge of failure mechanisms to perform visual inspection.

Third Party Inspection

Hidden defects such as discontinuities and corrosion are significant problems for owners of industrial plants. Discontinuities can result in structural failure in the material integrity of industrial assets or loss of containment, which can be costly in terms of repairs, lost production or contaminated products, environmental damage and potential risk to personnel.

That is why plant operators seek a third-party inspection company that provides a reliable and accurate Non-Destructive Testing method to identify hidden defects and corrosion locations that need to be monitored.

Please contact us to arrange or discuss your third party inspection requirements.

CONTACT INFO

Green NDT Services

20th km Raiwind Road,

Lahore, Pakistan.

Telephone: +92 42 3539 7481 - 2

Fax: +92 42 3539 7490

E-mail: mail@greenndt.com

CONTACT FORM

ABOUT THE GROUP

GREEN NDT SERVICES IS A RAVI GREEN (GROUP) COMPANY A PAKISTAN-BASED GROUP OF COMPANIES ESTABLISHED IN 1990 WITH THE CREATION OF RAVI GREEN ENGINEERING COMPANY, TO CATER TO THE OIL & GAS INDUSTRY IN PAKISTAN. TODAY, IT OPERATES IN PAKISTAN, AFGHANISTAN, IRAQ AND THE UNITED ARAB EMIRATES. WITH ACTIVE INTERESTS IN CONSTRUCTION, MECHANICAL ENGINEERING, LPG RETAIL/MARKETING, NON-DESTRUCTIVE TESTING, INSPECTION AND CONSULTANCY SERVICES.